Archives: 產品

Cold Finished Bar

WalsinLihwa stainless steel cold finished are made by cold drawing of wire rods or hot-rolled pickled bars and include round bars and bars of various shapes. WalsinLihwa produces a variety of cold finished bars at its Yenshui and Jiangyin plants; such cold finished bars feature high quality, stability, outstanding straightness, high precision, and ease in cutting. In addition to round bars in general, the Yenshui plant can supply centerless ground bars, square and hexagon cold finished bars, and is a world-leading supplier of stainless steel cold finished bars.

- Peeled Bar

Peeled bars are made by turning and feature high stability, an outstanding material strength and homogeneous structure, as well as precise straightness and sizes. The sizes of round peeled bars produced by the Yenshui plant range from 16 to 125 mm and those of peeled bars produced by the Yantai and Jiangyin plants range from 15 to 350 mm. - Cold Drawn Bar

Cold drawn bars have the outstanding features of accuracy, straightness, surface, cleanness and safety. Different kinds of soft/hard materials can be tailor-made according to customers’ requirement. The sizes of cold drawn bars in Yenshui are 2 – 70 mm, in Jiangyin are 2 – 128 mm. - Cold Drawn Shaped Bar

Cold-drawn shaped bars include square and hexagon bars. The sizes of hexagon bars and square bars produced by the Yenshui plant range from 4.76 to 63.5 mm and 4.76 to 40 mm respectively. The Jiangyin plant produces square and hexagon bars as well as other shaped bars. The sizes of its square bars and hexagon bars range from 12.7 to 76.2 mm, while customized development of other shaped bars is also provided by the plant.

Cold-Rolled Coil and Hot-Rolled Coil

Stainless steel hot-rolled black coils are made by hot rolling of slabs, and most of such coils are supplied to re-rollers. Hot-rolled no.1 coils are made of hot-rolled black coils by annealing and pickling; Cold-rolled coils — made from hot-rolled coils by cold rolling, annealing, picking, and quenching and tempering — are thinner, easy to be processed, and have a smooth surface.

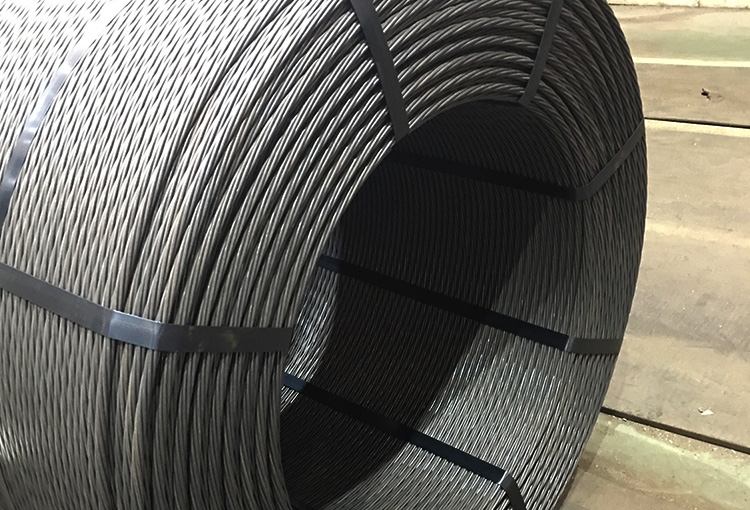

Steel Strand for Prestressed Concrete

Steel strands for prestressed concrete are made of the high carbon steel wire rods SWRH82B and have the characteristics of high tensile strength, low relaxation, steady modulus of elasticity, relieved stress, and high adhesion with concrete through continuous drawing with large deduction stranding and stabilization treatment to meet the ASTM A416, BS 5896, and GB/T5224 standards. Such steel strands are primarily used in highways, bridges, key water control projects, anchoring tension members, and lift tension members.

Copper Wire

Walsin Lihwa has ushered in the Southwire Continuous Rod (SCR) process from the U.S., Niehoff MM85 drawing machine from Germany, and SAMP drawing machine from Italy to produce 8.0 mm SCR copper rod and 2.6 mm hard drawn \ annealed copper wire featuring high purity and easy processability. Established in 1987, the Yangmei plant has an annual capacity of 180,000 tons of copper rod and 72,000 tons of copper wire. The Dongguan plant was established in 2000 and has an annual capacity of 80,000 tons of copper rod as well as 72,000 tons of copper wire.

- Copper Rod

The diameter is 8.0 mm, made from electrolytic copper, copper purity higher than 99.95%, and easy processing, raw material for the power cable and wire industry. - Copper Wire

The diameter is around 1.8 mm – 3.5 mm, apply for such as enameled wires, communication cables, and power cables and electronic wire. - Advantages and Features

1.Enhanced end product performance

2.Extended product life

3.Excellent drawability

4.Excellent fine-wire processability

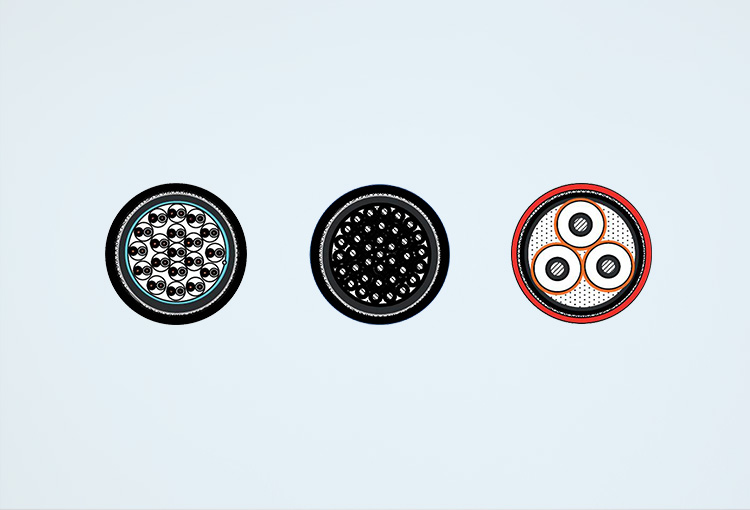

Shipboard Cable

The quality of Walsin Lihwa shipboard cables is highly reliable as all such cables have passed the IEC 60332-3-22 test for flame retardance and, in particular, the company’s flame-retardant and fire-resistant (FR-FA) products have passed the IEC 60331-21 test to ensure electricity self-sufficiency provided by the central power stations onboard of large vessels. Walsin Lihwa provides a full spectrum of medium-voltage shipboard cables, low-voltage control cables, instrument panel cables, and communication cables critical to onboard power stations to ensure the safety of lives and property enabled by the excellent flame retardancy and fire resistance of such cables.

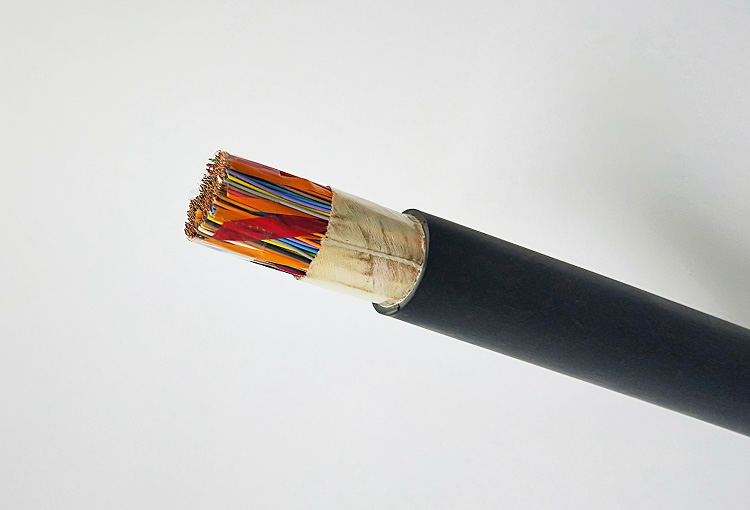

Copper Communication Cable

Since commencing manufacturing copper communication cables in 1969, Walsin Lihwa has been manufacturing various products of communication cable for telecommunications company, CATV, engineering, and network businesses for applications in underground and aerial cables, underground relay trunk lines, indoor telephone lines, high-speed transmission cables as well as monitoring and radio frequency systems. The communication cable plant is located in Hsinchuang Taiwan and the products are widely certificated by major telecommunications organizations.

Since its inception, Walsin Lihwa has been manufacturing indoor communication cables in Hsinchuang as well as supplying a variety of excellent quality and diversified range of copper cable products, and thus has long been an important supplier for Taiwan’s telecom construction.

Communication cable is qualified and certified by Chunghwa Telecom, and was rated as the highest rated manufacturer. The product quality and reputation have been widely recognized by the public.

- FS-JF-LAP Cable

Has an outstanding mechanical characteristic, which has good shielding and protection capabilities. Good waterproof, suitable for underground pipeline circuits and wiring network between exchange and subscribers. - FS-STP Cable

Has an outstanding mechanical strength, which is conducive to underground telecom cable. The cables are inflated with air to prevent moisture. It is suitable for the wiring network between the switching office and the user, the relay line between the office and the office, and in the environment of corrosion-resistant chemical as well as insect-resistant areas. - PE-PVC Cable

Light weight, durability, flame resistant, excellent shielding effect, and with a ripcord for easy stripping the cable jacket for installation. Suitable for indoor cabling. - CCP-LAP-SS Cable

Has an outstanding mechanical characteristic, which has good shielding and protection capabilities. Suitable for local feeding and telecommunication wiring in the city, and also can be used for the self-supporting aerial cable. - FS-LAP Cable

Has an outstanding mechanical characteristic, which has good shielding and protection capabilities. The cables are inflated with air to prevent moisture and are suitable for underground pipeline circuits and wiring network between exchange and subscribers. - Communication Cable

A communication cable consists of 4 twisted pairs. A twisted pair consists of 2 mutually insulated conductors that are twisted together for communication wiring. It is widely used in local area networks and is as the most commonly used network transmission medium for wiring. - Coaxial Cable

A coaxial cable consists of insulated copper conductor wires surrounded by a concentric conductor and its insulation layer, that is insulated and the whole cable is cladded by PVC. Featuring outstanding interference resistance and steady data transmission, coaxial cables are widely used in antenna signal reception, video surveillance systems, cable TV networks, and wired broadband networks.

Low Voltage Wire and Cable

Usage: Low voltage building wire, indoor and outdoor wiring, plant wiring, power transmission and distribution for industrial equipment.

Having been certified with CNS mark and Certificate of the Registration of Product Certification,

Walsin provides high-quality, safe, and reliable products for home buildings, malls, plants, and public infrastructure construction projects.

- PVC Wire and Cable

PVC insulated wire or PVC insulated, PVC sheathed cable, which are used in buildings, indoor wiring, plant wiring, and power transmission, distribution, control system for industrial equipment. - XLPE Cable

Cross-linked polyethylene (XLPE) cables under 2000V, with outstanding heat resistance, electrical, physical, and mechanical properties for uses in power supply and control wiring system in dry/ humid environments (indoors and outdoors). - Raw Copper Wire

Uninsulated raw copper wires or strands as ground wires or conductors for insulated wire and power cables

Wire Rod

The annual output of stainless steel wire rods is 240,000 tons, and a complete supply chain helps market products around the world, including America, Europe, Japan, Korea, Mainland China, Southeast Asia, Taiwan, as well as the emerging markets in East Europe. Available wire rod sizes range from 5.5 to 34.0 mm, and steel grades include the austenitic 200 and 300 series as well as the ferritic and martensitic 400 series. They meet the American Society for Testing and Materials (ASTM) requirements, Japanese Industrial Standards (JIS), as well as American Welding Society (AWS) requirements for welding wire rods. Moreover, WalsinLihwa can provide various sizes of wire rods based on customers’ special processing requirements.

Precision Foil

Walsin Precision Technology Sdn. Bhd. produces high-precision and super-thin metal materials for electronics, The complete production equipment at Walsin Precision Technology Sdn. Bhd. includes its 20HI precision Sendzimir rolling mill, stress bend leveler, continuous degreasing and annealing line, precision slitting machine, etc. The Malaysia plant can manufacture high quality stainless steel strips as thin as 0.02 to 1.5 mm with widths from 80 to 400 mm. Its annual capacity exceeds 10,000 tons. The products are primarily sold in Southeast Asia, Mainland China, Taiwan, Japan, and Korea, as well as Europe and the United States.