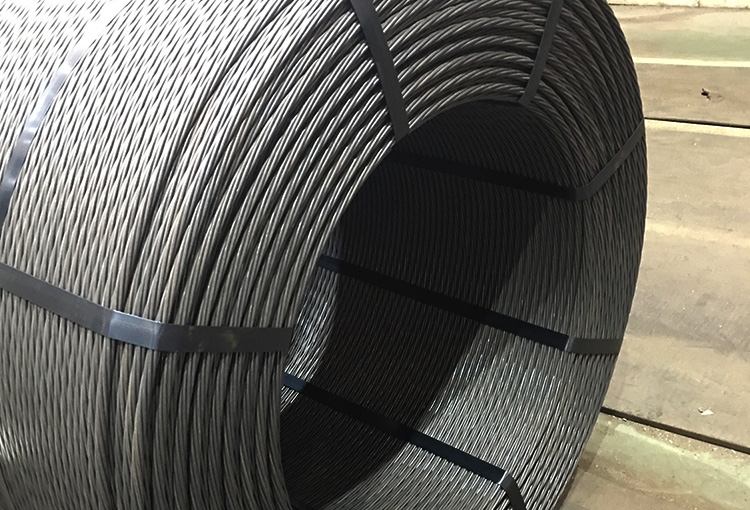

Steel strands for prestressed concrete are made of the high carbon steel wire rods SWRH82B and have the characteristics of high tensile strength, low relaxation, steady modulus of elasticity, relieved stress, and high adhesion with concrete through continuous drawing with large deduction stranding and stabilization treatment to meet the ASTM A416, BS 5896, and GB/T5224 standards. Such steel strands are primarily used in highways, bridges, key water control projects, anchoring tension members, and lift tension members.

產品分類: Steel Cable & Wire

Prestressed Steel Strand for Energy Purpose

Prestressed steel strands for energy purposes are made of high carbon steel wire rods SWRS82B and SWRH82B-2 and have the characteristics of high tensile strength, low relaxation, and steady modulus of elasticity, relieved stress, and high adhesion with concrete through continuous drawing with large deduction stranding and stabilization treatment to meet the EN10138, BS 5896, and GB/T5224 standards. Such steel strands are primarily used in wind turbines, liquefied natural gas (LNG) tanks, and nuclear reactor shields. Pre-stressed steel strands are the most ideal material for the main reinforcement bars of nuclear reactor shields because of their strengths such as high bearing capacity, low relaxation, great flexibility, and ease in binding. Such steel strands are used in construction of (LNG) tanks for their properties of good tensile strength and low-temperature static load anchoring. They are primarily used as the external cables on concrete wind turbine towers for their strengths in design flexibility and rapid construction to provide prefabrication, standardization, and preassembly solutions to concrete structures.

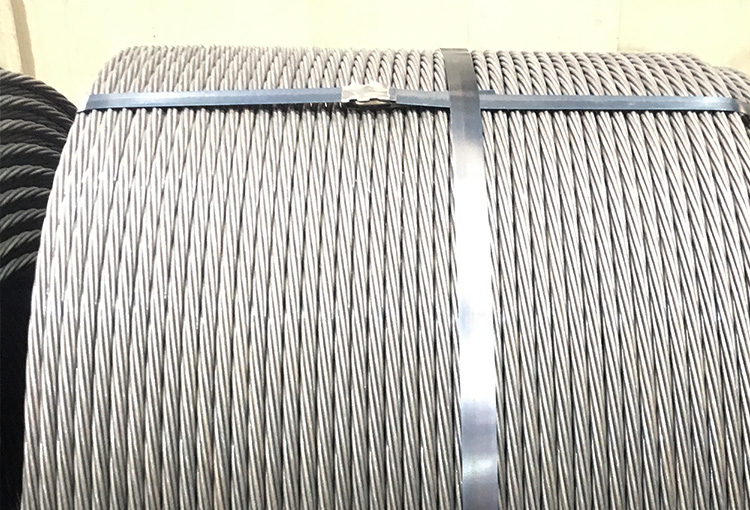

Hot-dip Zinc (zinc-aluminium or zinc-aluminium-magnesium) Coated Steel Wires for Bridge Cables

Hot-dip galvanized steel wires for bridge cables are made of high carbon steel wire rods and have the characteristics of high tensile strength, low relaxation, steady modulus of elasticity, great linearity, and strong resistance to corrosion through continuous drawing, hot- dip galvanization (with aluminum or magnesium), and stabilization treatment. Hot-dip galvanized steel wires are primarily used in the main cables of large-span suspension bridges, stay cables of cable-stayed bridges, and external reinforcement cables of various buildings and structures.

Hot-dip Zinc or Zinc-aluminium Coated Steel Wire Strand for Bridge Cables

The high-strength zinc- or aluminum-coated steel strands for bridge cables are made of high-carbon steel wire rods such as SWRS82B, SWRH82BCr, and SWRH82B-2, which undergo continuous drawing with large deduction stranding, hot dip galvanization, and stabilization to enable high tensile strength, low relaxation, and corrosion resistance to meet the standards of NF A35-035, GB/T 33369, and YB/T 152. Such steel strands are used in bridges, buildings, energy projects, and machines used in fields of hydraulic and geotechnical engineering.

Lubricated and HDPE Sheathed Steel Strands, Epoxy-coated Steel Strands

Unbonded steel strands are made of high carbon steel wire rods SWRH82B and have the characteristic of high tensile strength, strong resistance to corrosion, steady modulus of elasticity, relieved stress, low friction, separation from concrete, and mobility through continuous drawing, stabilization treatment, and resin and PE coating to meet the JG 161 and JT/T 771 standards. Unbonded steel strands are primarily used in prestressed steel structures, various highway and railway bridges, plant buildings, high-rise buildings, prestressed facilities, foundation pillars, building renovation reinforcement, overpasses, television towers, water towers, concrete silos, sewage disposal, rock anchoring, water resource management, and hydroelectricity infrastructure.

Epoxy-coated steel strands are made of high carbon steel wire rods SWRH82B and have the characteristic of high tensile strength, steady modulus of elasticity, relieved stress, high adhesion with concrete, outstanding insulation, strong resistance to cathode decomposition, a steady chemical property of coating, resistance to abrasion through continuous drawing with large deduction stranding, stabilization treatment, and epoxy coating to meet the GB/T 21073 standard. Epoxy-coated steel strands are primarily used in the bridges and electric poles where corrosion media are abound in their surroundings, as well as stay cables of cable-stayed bridges, chemical plant facilities, garages, and sewage disposal ponds.