Explore →

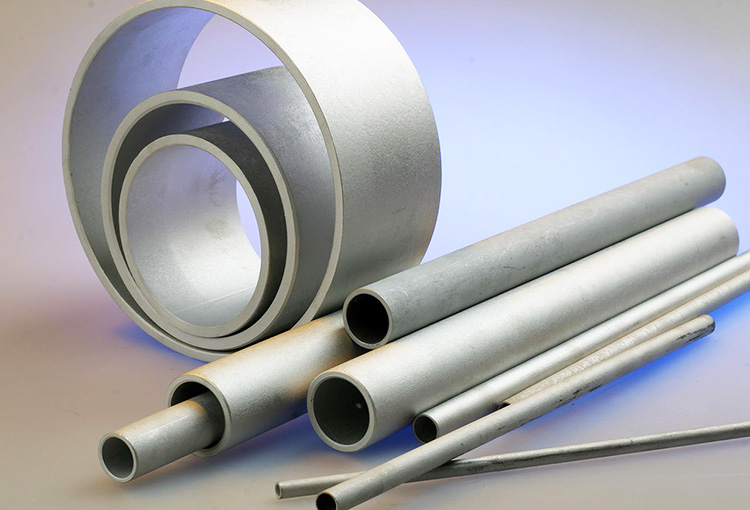

Steeval™ Cold Finished Bars are produced through the cold drawing of wire rods or hot-rolled pickled bars. The product range includes round, ground, square, and hexagon bars.

Manufactured at Walsin Lihwa’s Yenshui and Jiangyin plants, Steeval™ Cold Finished Bars are recognized for high quality, stability, straightness, dimensional accuracy, and enhanced machinability, making Walsin Lihwa one of the leading global suppliers in this segment.

To support diverse industrial applications, the bars are engineered for improved machinability, purity, wear resistance, heat resistance, and soft magnetic properties.

With strong R&D capabilities, reliable delivery, and responsive customer service, Steeval™ Cold Finished Bars provide comprehensive manufacturing support and are a dependable choice for precision stainless steel applications.

- Peeled Bar

Peeled bars are made by turning and feature high stability, an outstanding material strength and homogeneous structure, as well as precise straightness and sizes. The sizes of round peeled bars produced by the Yenshui plant range from 16 to 125 mm and those of peeled bars produced by the Yantai and Jiangyin plants range from 15 to 350 mm. - Cold Drawn Bar

Cold drawn bars have the outstanding features of accuracy, straightness, surface, cleanness and safety. Different kinds of soft/hard materials can be tailor-made according to customers’ requirement. The sizes of cold drawn bars in Yenshui are 2 – 70 mm, in Jiangyin are 2 – 128 mm. - Cold Drawn Shaped Bar

Cold-drawn shaped bars include square and hexagon bars. The sizes of hexagon bars and square bars produced by the Yenshui plant range from 4.76 to 63.5 mm and 4.76 to 40 mm respectively. The Jiangyin plant produces square and hexagon bars as well as other shaped bars. The sizes of its square bars and hexagon bars range from 12.7 to 76.2 mm, while customized development of other shaped bars is also provided by the plant.