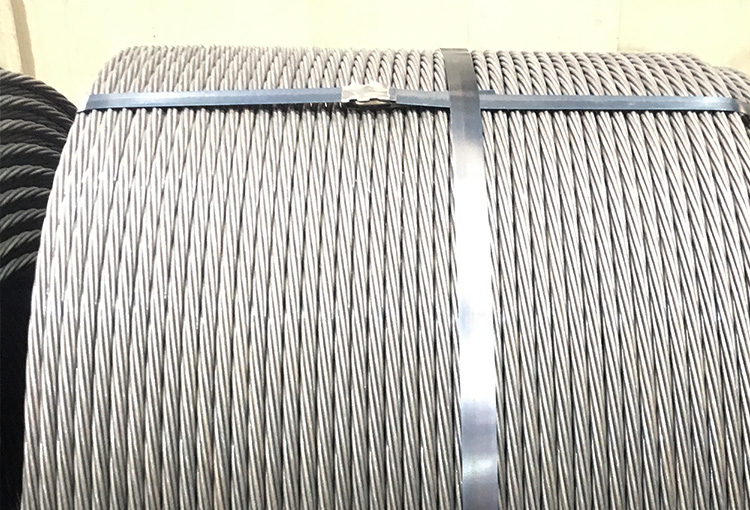

Prestressed steel strands for energy purposes are made of high carbon steel wire rods SWRS82B and SWRH82B-2 and have the characteristics of high tensile strength, low relaxation, and steady modulus of elasticity, relieved stress, and high adhesion with concrete through continuous drawing with large deduction stranding and stabilization treatment to meet the EN10138, BS 5896, and GB/T5224 standards. Such steel strands are primarily used in wind turbines, liquefied natural gas (LNG) tanks, and nuclear reactor shields. Pre-stressed steel strands are the most ideal material for the main reinforcement bars of nuclear reactor shields because of their strengths such as high bearing capacity, low relaxation, great flexibility, and ease in binding. Such steel strands are used in construction of (LNG) tanks for their properties of good tensile strength and low-temperature static load anchoring. They are primarily used as the external cables on concrete wind turbine towers for their strengths in design flexibility and rapid construction to provide prefabrication, standardization, and preassembly solutions to concrete structures.

Archives: 產品

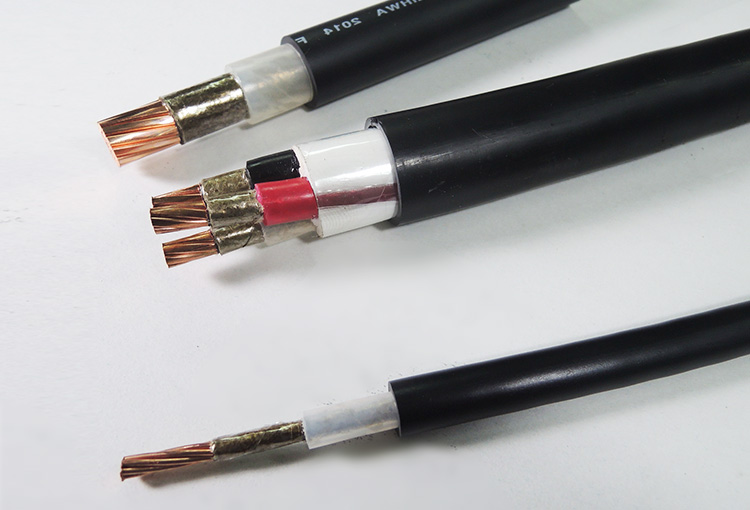

Heavy Machinery / Crane Cable

Walsin Lihwa produces power cables for heavy duty machine such as overhead cranes, spreader baskets, quayside container gantry cranes, and quay cranes. They are all abrasion resistant, bending resistant, and twist resistant with outstanding dynamic tensile force and impact endurance. Their flexible conductor structures are repeatedly bendable enough to meet European specifications, and their 5GM5 compound sheath has better abrasion resistance and mechanical characteristic to make them more compact, lightweight, and durable.

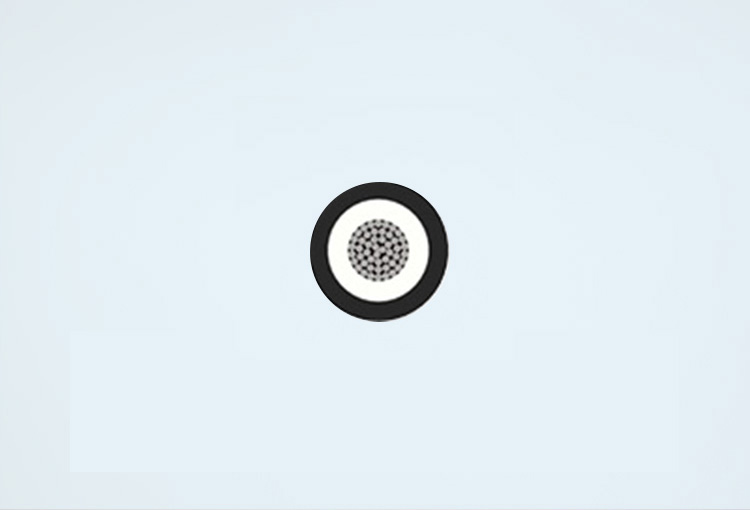

Optical Fiber Cable

In 1993 Walsin Lihwa commenced manufacturing slotted ribbon-type optical fiber cables in Hsin Chuang, and has been the first company whose products are entitled to Chunghwa Telecom’s simplified inspection. Walsin Lihwa provides integrated services of R&D, sales, and engineering for the customization of various specialty optical cables, for example, the first ever compound cable in Taiwan that combines the properties of copper, optical, and power cables, and is applicable to a fire-control system of the Chungshan Institute of Science and Technology. Quantity production of such compound cables has commenced. Moreover, there is a type of indoor eco-material optical cables to improve the pollution shortcomings of conventional plastic pigtail optical cables that may incur public hazards.

Walsin Lihwa also sells fiber ribbons to fiber optic manufacturers.

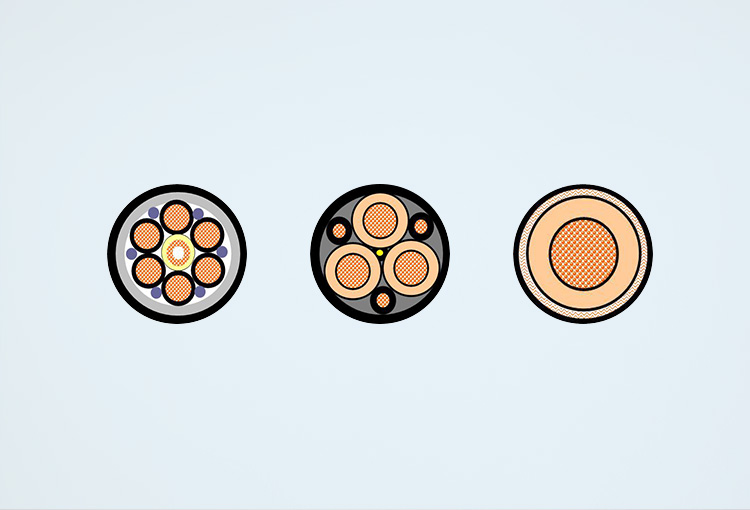

- Slotted Ribbon Type Optical Fiber Cable

Compliant with the ITU-T and Chunghwa Telecomm specifications, with small outer diameter and multiple cores. Suitable for metropolitan areas for easy identification by color of each optical fiber wire and simultaneous joint of four cores for time-saving. - Loose Tube Type Optical Fiber Cable

Compliant with the ITU-T and Chunghwa Telecomm specifications, easy bending and implementation in the connecting box, and easy identification by color of each optical fiber wire. - Indoor Type Optical Fiber Cable

Compliant with the ITU-T and Chunghwa Telecomm specifications, Provide maximum flexibility and working convenience. Low-smoke, halogen-free, and flame retardant sheath. Suitable for high-rise building and household cabling. - Uni-tube Fiber Optic Cable

Compliant with the ITU-T, provide maximum flexibility and working convenience. The PE sheath is weatherproof, suitable for outdoor communication wiring. Low-smoke, halogen-free, and flame retardant sheath, suitable for high-rise building and household cabling. - Flat Fiber Optic Cable

Compliant with the ITU-T, featured with simple structure, lightweight, bendable and resistant to lateral pressure. Suitable for horizontal cabling in high-rise building and household.

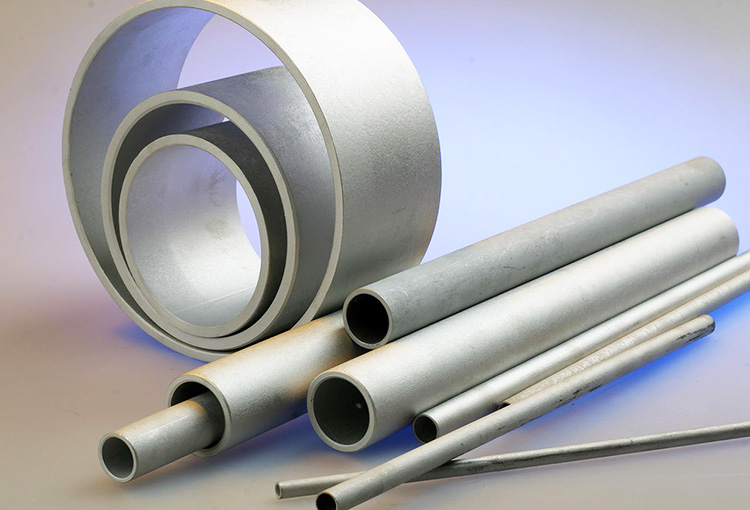

Seamless Pipes and Tubes

Changshu Walsin Specialty Steel Co., Ltd. located in Changshu, Jiangsu Province, with annual production capacity of 30,000 tons. Changshu manufactures seamless pipes and tubes in stainless steel, nickel alloy and other alloy grades. Walsin Lihwa’s Yenshui and Yantai plant, and European subsidiary CAS and SMP provide materials and various grades of steel to the Changshu Walsin, enabling the Changshu operation to provide a complete product sizes and guarantee outstanding product quality. Moreover, complete test facilities at this plant help meet the Chinese National Standards (Guobiao), Japanese Industrial Standards (JIS), European Norm (EN), and RCC-M (Règles de Conception fundamentals for nuclear manufacturers), having the American Society for Test and Material (ASTM) Certificate, American Society of Mechanical Engineering (ASME) Certificate, DeutschesInstitutfürNormung (DIN) Certificate, too, to meet customer requirements for quality. Changshu Walsin provides stainless steel seamless pipes and tubes with outside diameters of 3.18 – 530 mm and wall thickness of 0.50 – 50 mm. Such corrosion-, erosion-, and heat-resistant pipes and tubes are primarily provided to chemical engineering, chemical fertilizer, and oil refining plants as well as boiler heat exchange exchangers.

WalsinLihwa exports its seamless stainless steel pipes and tubes from Mainland China to America, Europe, Japan, Korea, the Middle East, Southeast Asia, and Taiwan for the automobile, boiler, petrochemical, power generation, nuclear energy, and shipbuilding industries there. Such corrosion-, erosion-, and heat-resistant pipes and tubes are suitable forthe boiler heat exchangers at chemical engineering, chemical fertilizer, and oil refining plants. Featuring high quality of products and sale service, Changshu Walsin Specialty Company is a qualified supplier designated by internationally-renowned chemical consortiums such as DuPont, Dow Chemical, Fluor Technip, BASF, Bayer, Shell, and Petrobras as well as reputed petrochemical consortiums in Mainland China such as Sinopec, PetroChina, andChina National Offshore Oil Corporation. Changshu Walsin Specialty Company is also a long-term supplier to famous local and overseas power station boiler manufacturers such as B&W, Foster Wheeler, Shanghai Boiler Works Company, and Harbin Boiler Company as well as the nuclear power plants in Lingao, Shenzhen; Hongyan River, Liaoning; Ningde, Fujian; and Yangjiang, Guangdong.

Hot-dip Zinc (zinc-aluminium or zinc-aluminium-magnesium) Coated Steel Wires for Bridge Cables

Hot-dip galvanized steel wires for bridge cables are made of high carbon steel wire rods and have the characteristics of high tensile strength, low relaxation, steady modulus of elasticity, great linearity, and strong resistance to corrosion through continuous drawing, hot- dip galvanization (with aluminum or magnesium), and stabilization treatment. Hot-dip galvanized steel wires are primarily used in the main cables of large-span suspension bridges, stay cables of cable-stayed bridges, and external reinforcement cables of various buildings and structures.

Wind Turbine Cable

Torsion ability is particularly important to wind turbine cables because such cables moves along with wind turbine blades during power generation. If they are not torsion resistant enough and their cores break, wind turbines may break down to incur fires or other accidents. In order to provide such cable, Walsin Lihwa develops wind turbine cable successfully and has obtained patents in Taiwan (patent certificate no. M426854), Mainland China (patent certificate no.201120509692.4), and the U.S. (patent certificate no. US8,729,390 B2). According to the U.S. National Electrical Code, wind turbine tray cables (WTTC) are the power cables that can be installed in wind turbine cable trays or ducts. In the Underwriters Laboratories (UL) certification category of ZGZN, Walsin Lihwa wind turbine cables have been certificated for resistance to cold bending, oils, sunlight, and twisting to meet the UL RHW-2 specifications.

Fire Resistant Cable / Heat Resistant Cable

According to the Standard for Installation of Fire Safety Equipments Based on Use and Occupancy, wiring of the fire safety equipment emergency power supply system shall be fire-resistant or heat-resistant.

Meeting the「Approval Criteria for Heat Resistant Wires and Cables」and the 「Approval Criteria for Fire Resistant Cables」, Walsin Lihwa’s fire-resistant wires and cables have gain relevant accreditations. For a certain period of time, the products can maintain normal operation of the fire safety equipment, which use emergency power supply in case of fires, to help protect lives and property.

- Heat Resistant Cable

Heat-resistant wires and cables for signals, indicator lights, and control circuits of emergency power supply of fire safety equipment under 600V. - Flame Resistant Cable

Flame-resistant cables for power supply, control circuits, alarms, monitoring, and communications of emergency power supply of fire safety equipment under 600V.

Hot-Rolled Bar

WalsinLihwa hot-rolled stainless steel bars are made of stainless steel billets and ingots through hot rolling, and they can be processed into peeled bars through annealing and peeling. The sizes of hot-rolled round bars and forged round bars produced by the Yantai plant range from 16 to 130 mm and 140 to 320 mm respectively.

- Continuously Cast Billet

Round Ballet: 150/160/180/200/260

Square Ballet: 150/160/180/200

Length: 4~10M - Ingot

12/15/20/22/24/32″ - Peeled Bars

Peeled bars are made by turning and feature high stability, an outstanding material strength and homogeneous structure, as well as precise straightness and sizes. The sizes of peeled bars produced by the Yantai plant and Yenshui plant range from 16 to 300 mm and 16- 120 mm respectively.

Hot-dip Zinc or Zinc-aluminium Coated Steel Wire Strand for Bridge Cables

The high-strength zinc- or aluminum-coated steel strands for bridge cables are made of high-carbon steel wire rods such as SWRS82B, SWRH82BCr, and SWRH82B-2, which undergo continuous drawing with large deduction stranding, hot dip galvanization, and stabilization to enable high tensile strength, low relaxation, and corrosion resistance to meet the standards of NF A35-035, GB/T 33369, and YB/T 152. Such steel strands are used in bridges, buildings, energy projects, and machines used in fields of hydraulic and geotechnical engineering.

PV Cable

Walsin Lihwa PV cables have EN, UL, and S-JET certifications. PV cables are always used under high temperatures and must be resistant to heat, humidity, and sunlight. The UL, for example, requires USE-2 cables and PV cables stand for temperature higher than 90°C in a humid environment. PV cables are installed outdoors and also must pass a 720-hour weatherproof test as well as a -40°C low-temperature resistance test. The structure of PV cables is relatively simple and uncertified PV cables cannot reach the product life expectancy. Replacing uncertified PV cables is very costly and troublesome; on the other hand, certificated PV cables save maintenance costs significantly to enable more cost-efficient solar power generation.