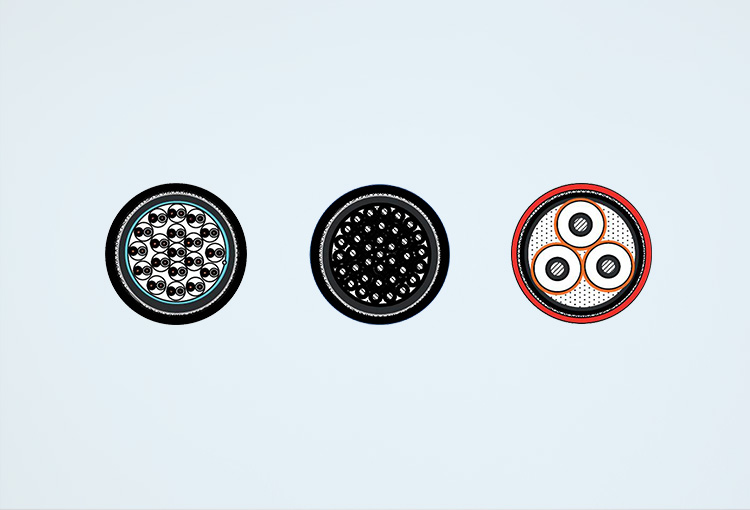

The quality of Walsin Lihwa shipboard cables is highly reliable as all such cables have passed the IEC 60332-3-22 test for flame retardance and, in particular, the company’s flame-retardant and fire-resistant (FR-FA) products have passed the IEC 60331-21 test to ensure electricity self-sufficiency provided by the central power stations onboard of large vessels. Walsin Lihwa provides a full spectrum of medium-voltage shipboard cables, low-voltage control cables, instrument panel cables, and communication cables critical to onboard power stations to ensure the safety of lives and property enabled by the excellent flame retardancy and fire resistance of such cables.

產品分類: Industrial Cable

Heavy Machinery / Crane Cable

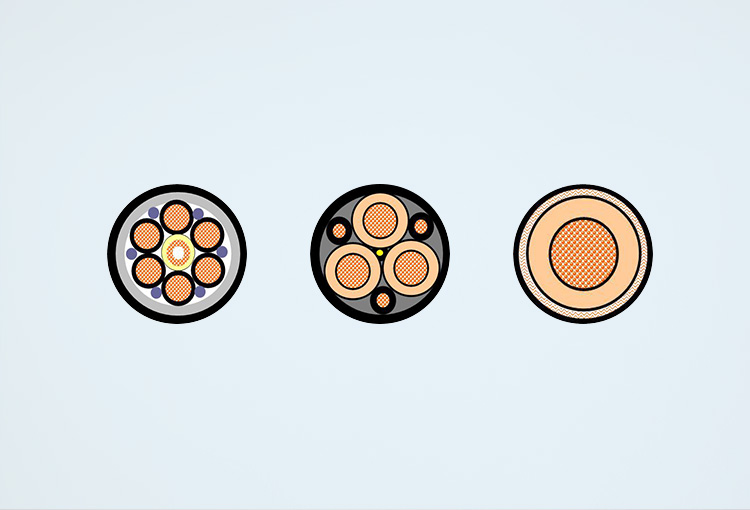

Walsin Lihwa produces power cables for heavy duty machine such as overhead cranes, spreader baskets, quayside container gantry cranes, and quay cranes. They are all abrasion resistant, bending resistant, and twist resistant with outstanding dynamic tensile force and impact endurance. Their flexible conductor structures are repeatedly bendable enough to meet European specifications, and their 5GM5 compound sheath has better abrasion resistance and mechanical characteristic to make them more compact, lightweight, and durable.

Wind Turbine Cable

Torsion ability is particularly important to wind turbine cables because such cables moves along with wind turbine blades during power generation. If they are not torsion resistant enough and their cores break, wind turbines may break down to incur fires or other accidents. In order to provide such cable, Walsin Lihwa develops wind turbine cable successfully and has obtained patents in Taiwan (patent certificate no. M426854), Mainland China (patent certificate no.201120509692.4), and the U.S. (patent certificate no. US8,729,390 B2). According to the U.S. National Electrical Code, wind turbine tray cables (WTTC) are the power cables that can be installed in wind turbine cable trays or ducts. In the Underwriters Laboratories (UL) certification category of ZGZN, Walsin Lihwa wind turbine cables have been certificated for resistance to cold bending, oils, sunlight, and twisting to meet the UL RHW-2 specifications.

PV Cable

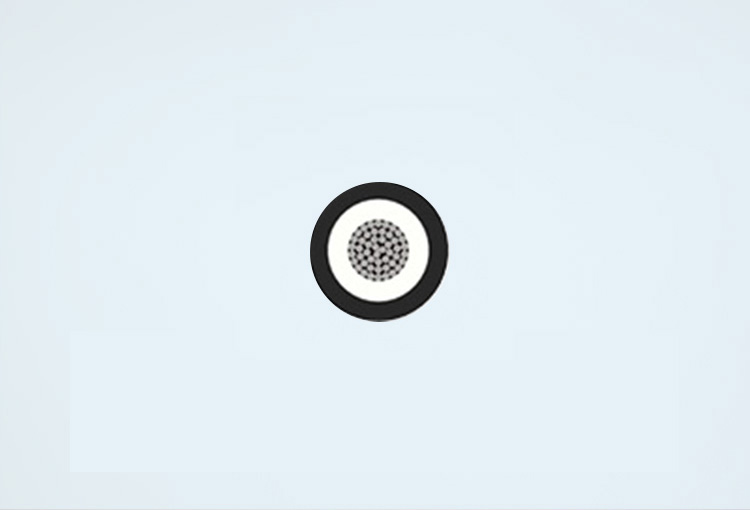

Walsin Lihwa PV cables have EN, UL, and S-JET certifications. PV cables are always used under high temperatures and must be resistant to heat, humidity, and sunlight. The UL, for example, requires USE-2 cables and PV cables stand for temperature higher than 90°C in a humid environment. PV cables are installed outdoors and also must pass a 720-hour weatherproof test as well as a -40°C low-temperature resistance test. The structure of PV cables is relatively simple and uncertified PV cables cannot reach the product life expectancy. Replacing uncertified PV cables is very costly and troublesome; on the other hand, certificated PV cables save maintenance costs significantly to enable more cost-efficient solar power generation.

Electric Vehicle Cable

- EV High Voltage Cable

The conductor and shielding of Walsin Lihwa electric vehicle cables are flexible and soft enough for electric vehicle assembly. Such cables are resistant to abrasion, flame, heat, humidity, interferences, low temperatures, oils, and ozone. Especially, oil resistance passes 8 internationally designated machine oils for vehicles. Combination of high quality copper and XLPO for high temperature insulation to accommodate high current loads on electric vehicles. Soft PVC coating is heat resistant up to 105°C, and XLPO insulation as well as XLPO coating are heat resistant up to 125°C and 150°C respectively. - Electric Vehicle Charging Plug

CCS1 and CCS2 DC charging plugs comply with CNS 15700, IEC 62196, and UL 2251 standard. CCS1 DC charging plug is the first charging plug product to obtain VPC(Voluntary Product Certification) in Taiwan, therefore taking a leading position in the industry regarding quality and related regulations. The charging plug includes a cable with connector, and can be installed on electric vehicle charging station. The surface of current and signal pins is silver-plated. The handle is ergonomically designed and user-friendly. Built-in temperature sensors can detect operation temperature of current contacts. In terms of application and operation, this series of product can meet customer’s needs, and is the top choice in the market regarding quality and durability. - Electric Vehicle Charging Cable

AC/DC charging cables comply with IEC 62893 and UL 62 standard. Based on customer’s needs, customized products are also available. Charging cables perform the functions of power transmission, signal control, and data exchange. In addition, the cable’s features meet the requirements of regulations, including: softness, toughness, abrasion resistance, pull resistance, oil resistance, corkscrew resistance, weather resistance, and environmental requirements. The cable can be applied to home, public, and supercharging stations, and meet market demand immediately.

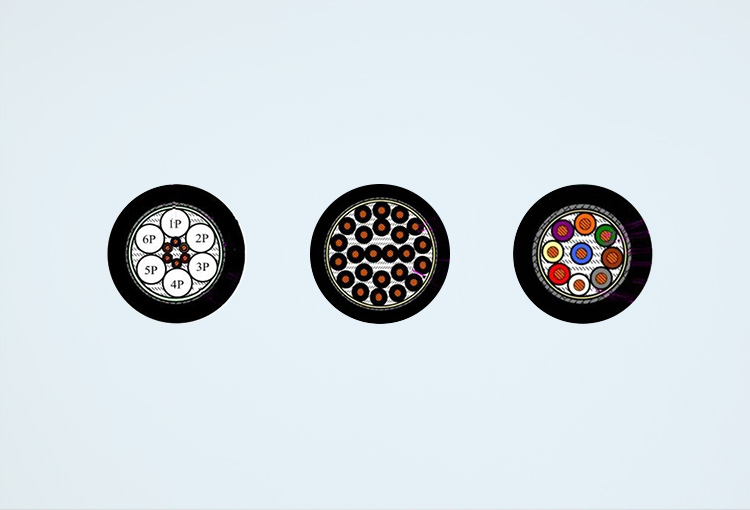

Flexible Cable

Power and signal are main application for flexible cable, which widely used in automation, machine tools, servomotors, and robots. Due to various equipment, demand comes small-volume but specification is large-variety. Domestic cable manufacturers require minimum order quantity (MOQ). As a result, most flexible cables are imported. Walsin Lihwa focuses on automation equipment manufacturers featuring high unit prices and high value-added and offers “low MOQ”, “low inventory” and “delivery service” to strengthen local advantages and being a reliable partner to the industry.