Flames, dense smoke, and high temperature are the three acute dangers during fires. Smoke is the most fatal of them because: Smoke-inhalation may lead to death. Visual obscuration during escape from fires occurs. Corrosive and toxic gases contained in the smoke jeopardize lives and equipment.

Widely used in public places such as airports, hospitals, mass rapid transit systems, and underground railways, LSFH cables are highly safe power transmission and distribution products with the following characteristics:

.Outstanding fire resistance (Flame propagation test)

.Extremely low density of smoke when being burnt (Smoke test)

.Near-zero toxicity index (Toxicity index test)

.High corrosion resistance(combustible gas test)

.High oxygen index, without concern of supporting combustion (Oxidation and temperature index test)

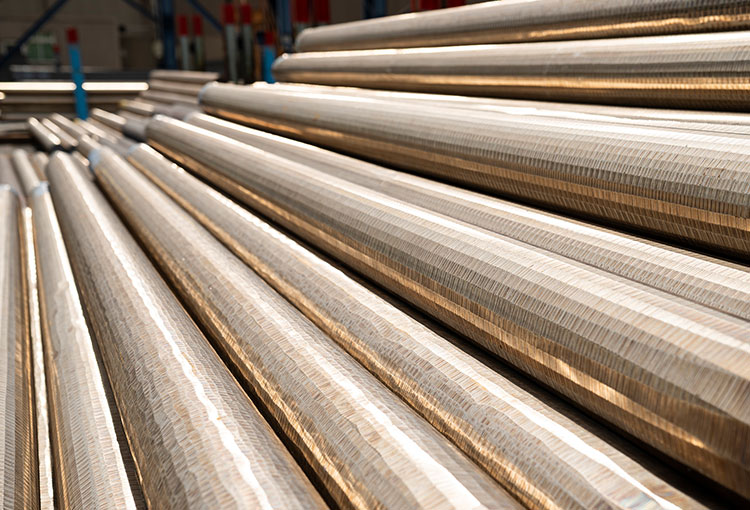

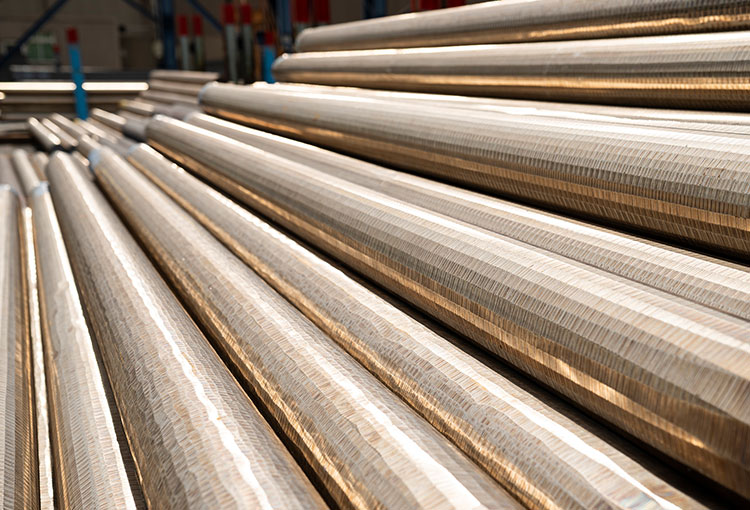

Unbonded steel strands are made of high carbon steel wire rods SWRH82B and have the characteristic of high tensile strength, strong resistance to corrosion, steady modulus of elasticity, relieved stress, low friction, separation from concrete, and mobility through continuous drawing, stabilization treatment, and resin and PE coating to meet the JG 161 and JT/T 771 standards. Unbonded steel strands are primarily used in prestressed steel structures, various highway and railway bridges, plant buildings, high-rise buildings, prestressed facilities, foundation pillars, building renovation reinforcement, overpasses, television towers, water towers, concrete silos, sewage disposal, rock anchoring, water resource management, and hydroelectricity infrastructure.

Epoxy-coated steel strands are made of high carbon steel wire rods SWRH82B and have the characteristic of high tensile strength, steady modulus of elasticity, relieved stress, high adhesion with concrete, outstanding insulation, strong resistance to cathode decomposition, a steady chemical property of coating, resistance to abrasion through continuous drawing with large deduction stranding, stabilization treatment, and epoxy coating to meet the GB/T 21073 standard. Epoxy-coated steel strands are primarily used in the bridges and electric poles where corrosion media are abound in their surroundings, as well as stay cables of cable-stayed bridges, chemical plant facilities, garages, and sewage disposal ponds.

The rubber material is a thermosetting elastomer, which has the characteristics of good flexibility, weather resistance, abrasion resistance, and spark resistance.

It is commonly used for EPR (Ethylene Propylene Rubber) as power cable insulation.

Although the electrical properties are inferior to XLPE, but it has better weather resistance, as well as flame retardant. Thus, suitable for cable insulation materials which are to be used in thermal power plants, nuclear power plants and other places.

- Neoprene rubber material

has good weather resistance, flame retardant, abrasion resistance as well as tensile strength, and is often used as a covering material for rubber cables.

- Hypalon rubber material

has excellent heat resistance, often used as an outer sheath for rubber cables. This material is also flexible and has good electrical characteristics. Thus, it can be used as an insulation layer for the lead wires of low-voltage electric machines.

The Hypalon lead wires, EPR-Neoprene cables, EPR-Hypalon cables, and EPR-LSFH cables produced by Walsin Lihwa are suitable for industrial equipment cables, as well as special cables, such as generators, electric welders, and lead wires of electric machines.

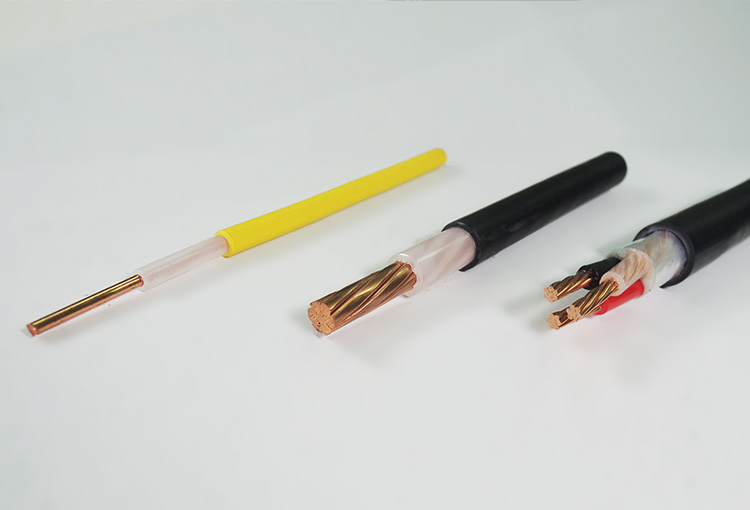

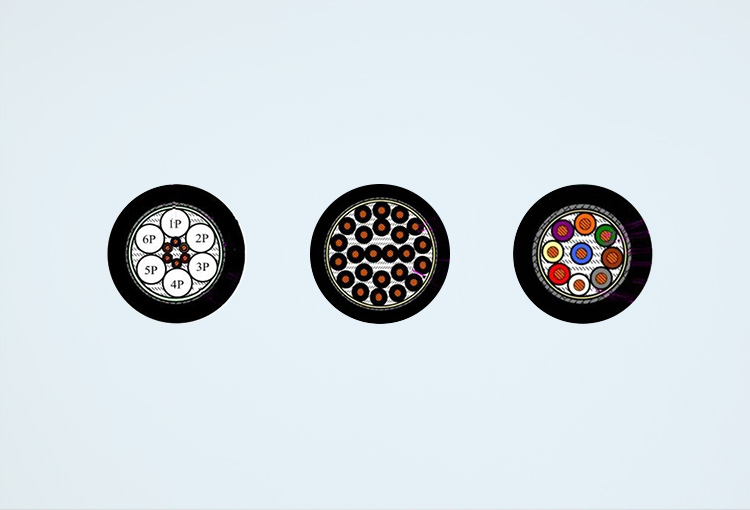

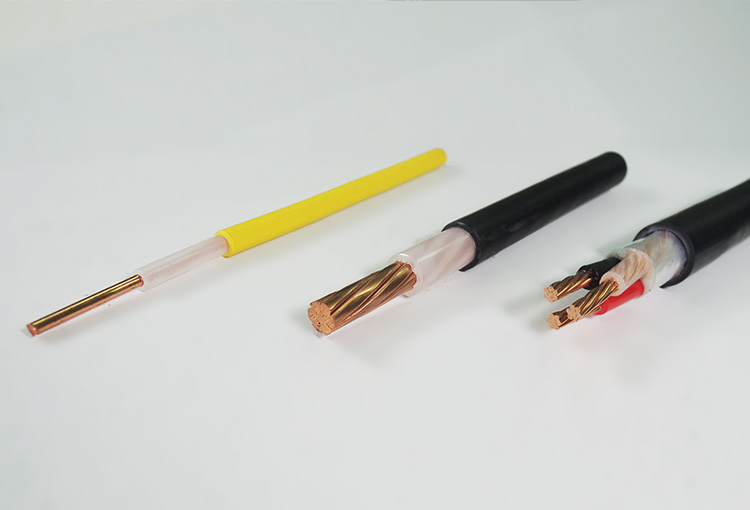

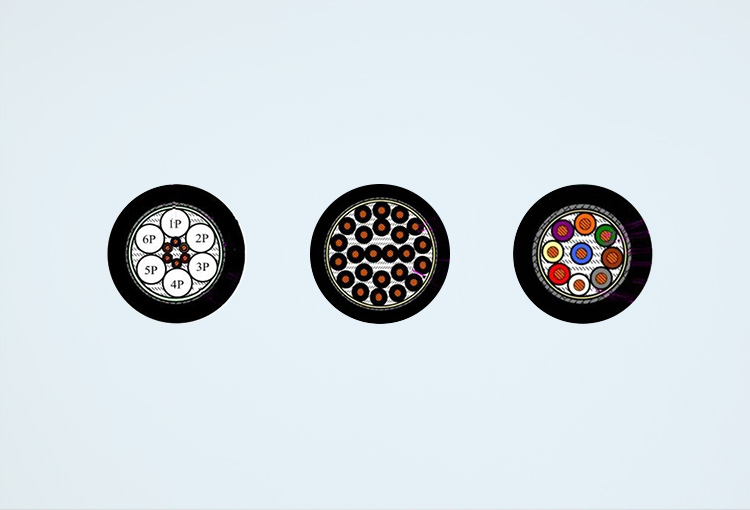

Power and signal are main application for flexible cable, which widely used in automation, machine tools, servomotors, and robots. Due to various equipment, demand comes small-volume but specification is large-variety. Domestic cable manufacturers require minimum order quantity (MOQ). As a result, most flexible cables are imported. Walsin Lihwa focuses on automation equipment manufacturers featuring high unit prices and high value-added and offers “low MOQ”, “low inventory” and “delivery service” to strengthen local advantages and being a reliable partner to the industry.

Medium- and high-voltage XLPE cables feature outstanding heat resistance as well as good electrical, physical and mechanical characteristics, and are suitable for indoor and outdoor power transmission and distribution systems as well as dry and humid environments.

The conductor temperature can reach 90°C under normal conditions, 130°C under an emergency conditions(no more than 3 times in 12 consecutive months, with an average of no longer than 36 hours each time), and it can reach 250°C during a short circuit maximum up to 5 seconds.

Such cables are suitable for urban underground distribution as well as medium- and high-voltage power transmission and distribution in various public places, plant buildings, residential communities, and multi-story buildings.

WalsinLihwa produces stainless steel billets, slabs, and ingots of different specifications. They can be rolled into wire rods, cold finished bars, seamless pipes and tubes, and various forged items, and all these products can be customized according to customer requirements. The diameters of round billets produced by the Yenshui plant range from 160, 180, 200, to 240 mm. The sizes of its square billets are 155 and 205 mm. Its slabs are 200 mm thick and 1,000 to 1,280 mm wide. The bloom size is 220 mm thick and 330 mm wide The Yantai plant’s stainless steel billets and ingots are mainly the austenitic grade, and the diameters of its round billets range from 150, 160, 180, 200, 220 to 260 mm; the diameters of its square billets range from 150, 160, 180, to 200 mm; and the diameters of its stainless steel ingots range from 12, 15, 20, 22, 24 to 32 inches.